Laser Cladding Pumps & Valves

Laser cladding is widely used in the oil, gas, and petrochemical industries to provide a protective surface coating on metal parts. Applications for laser cladding in this industry include bearings, bearing bushes, bearing journals, cutting and drilling components and tools, gate and ball seats and valves, heat exchangers, hydraulic cylinders and plungers, piston rods, pump components, risers, rotors, seals and seal seats, and tanks.

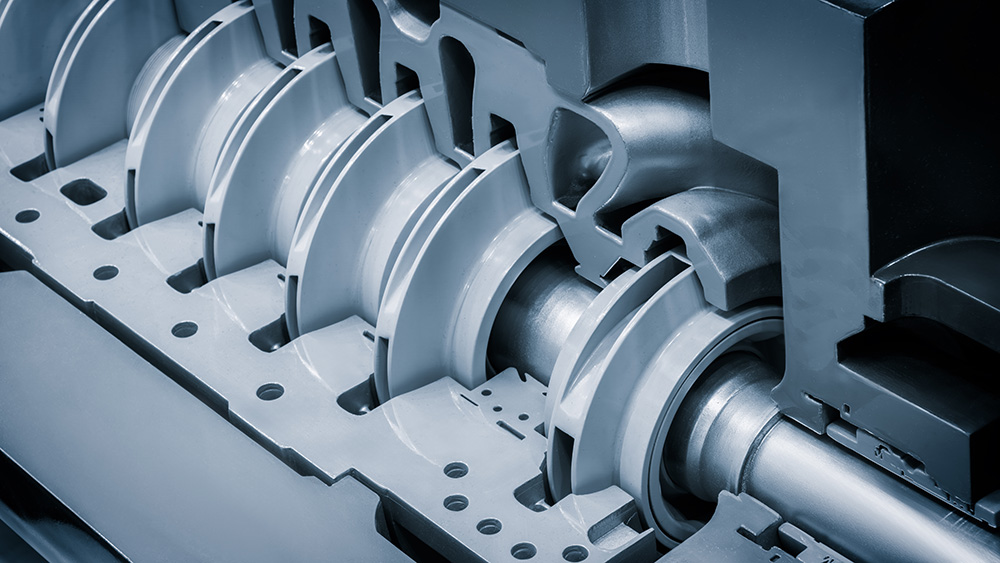

Extend the life of critical service pumps

Laser cladding technology is widely used to restore aged and corroded pump housings, impellers, wear rings and pump shafts. The benefits of laser cladding in extending the life of critical equipment by precisely depositing material to rebuild damaged areas and enhance resistance to future wear and corrosion. This process is particularly beneficial for housings that are no longer in production, as it provides a cost-effective alternative to fabricating new components, additionally, laser cladding ensures minimal heat input, reducing the risk of thermal distortion and maintaining the integrity of the original structure.

High performance ball & gate valves

Laser cladding has been adopted to enhance ball valve performance by applying high-hardness alloy layers to the surface of ball & gate valves. This technique significantly improves their durability, stability, and overall performance by providing enhanced wear and corrosion resistance and ensures smooth and precise sealing surfaces, enhancing sealing reliability.

Increase Service Life

The process is becoming increasingly popular due to its cost-effectiveness and outstanding quality of coatings

The use of copper-tin alloys, such as bronze, for coating the outer diameter of the shaft, creates a durable and robust bonding between the base material and the coating materials. This method not only reduces frictional resistance but also increases the service life of the components.

Laser Cladding System Solutions with Total Support

Laser Cladding enhances durability, wear, and corrosion resistance for oil, gas, and petrochemical industry components, ensuring cost-effective restoration.

Our Laser Systems and Total Support ensures the optimum outcome and performance for your application.

Frequently asked questions

Yes, laser cladding usually achieves target hardness in a single 1.5mm layer, whereas PTA may need two. Achieve the same hardness with a thinner layer and less dilution.