Laser Cladding Systems and Equipment

Hornet’s laser cladding solutions are engineered for flexibility and precision. Systems can be equipped with standard or high-power EHLA, conventional cladding, wide beam, or internal processing. The portfolio includes large-scale turnkey systems up to 26 metres between centres and up to 13 fully integrated and interpolated axes, the Hive™ platform in four fully preconfigured versions, and the Hornet Mobile™ system, purpose-built for on-site cladding of large or fixed components.

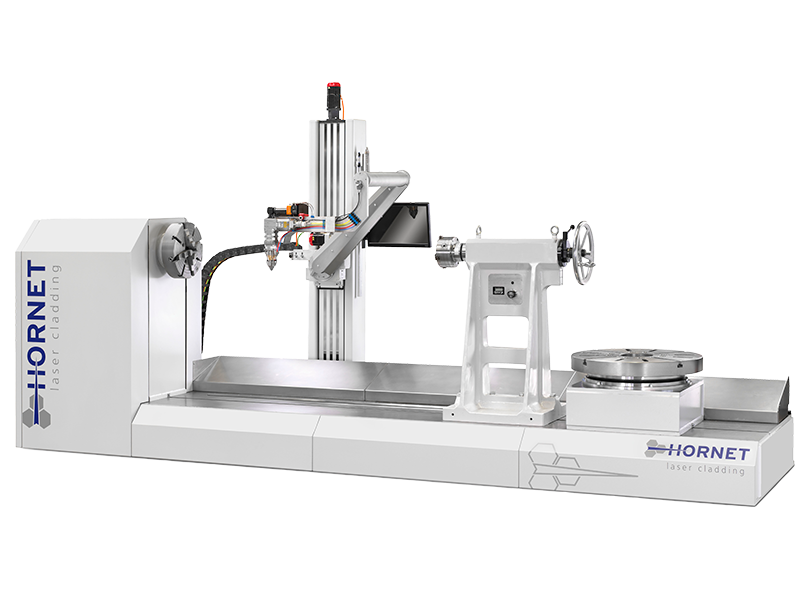

Turnkey Laser Cladding Systems

Complete systems in various sizes and setups, up to 26 metres. Available with robotic or CNC control and optional internal laser cladding.

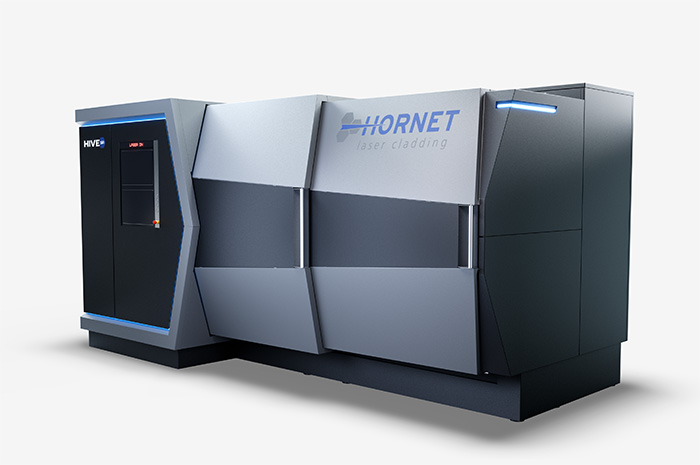

The Hive™ Laser Cladding System

Compact laser cladding system available in two sizes, with Cartesian or robotic control options.

Hornet Mobile™ Laser Cladding System

Compact, portable, and easy to lift. Designed for on-site repair of large or fixed components that cannot be transported.

Frequently asked questions

A wide range of materials can be applied using the laser cladding process, including:

Nickel-based alloys, Cobalt-based alloys, Stainless Steels, Iron-based alloys, Copper, Titanium, and even Aluminium.