What is Laser Cladding Technology?

Laser cladding technology has been used for many years in a wide variety of industries to provide metal components with improved functional surfaces. The process is a weld build-up process and is increasingly used instead of PTA (Plasma Transferred Arc) welding and easily outperforms conventional welding methods like TIG (Tungsten Inert Gas) for advanced weld repair applications.

Which Substrates Are Suitable for Laser Cladding?

Laser cladding works effectively on a broad range of metals, from steels and superalloys to non-ferrous materials. Thanks to its precise heat control, it creates a strong bond with minimal distortion, enabling repairs and coatings on challenging materials like cast iron.

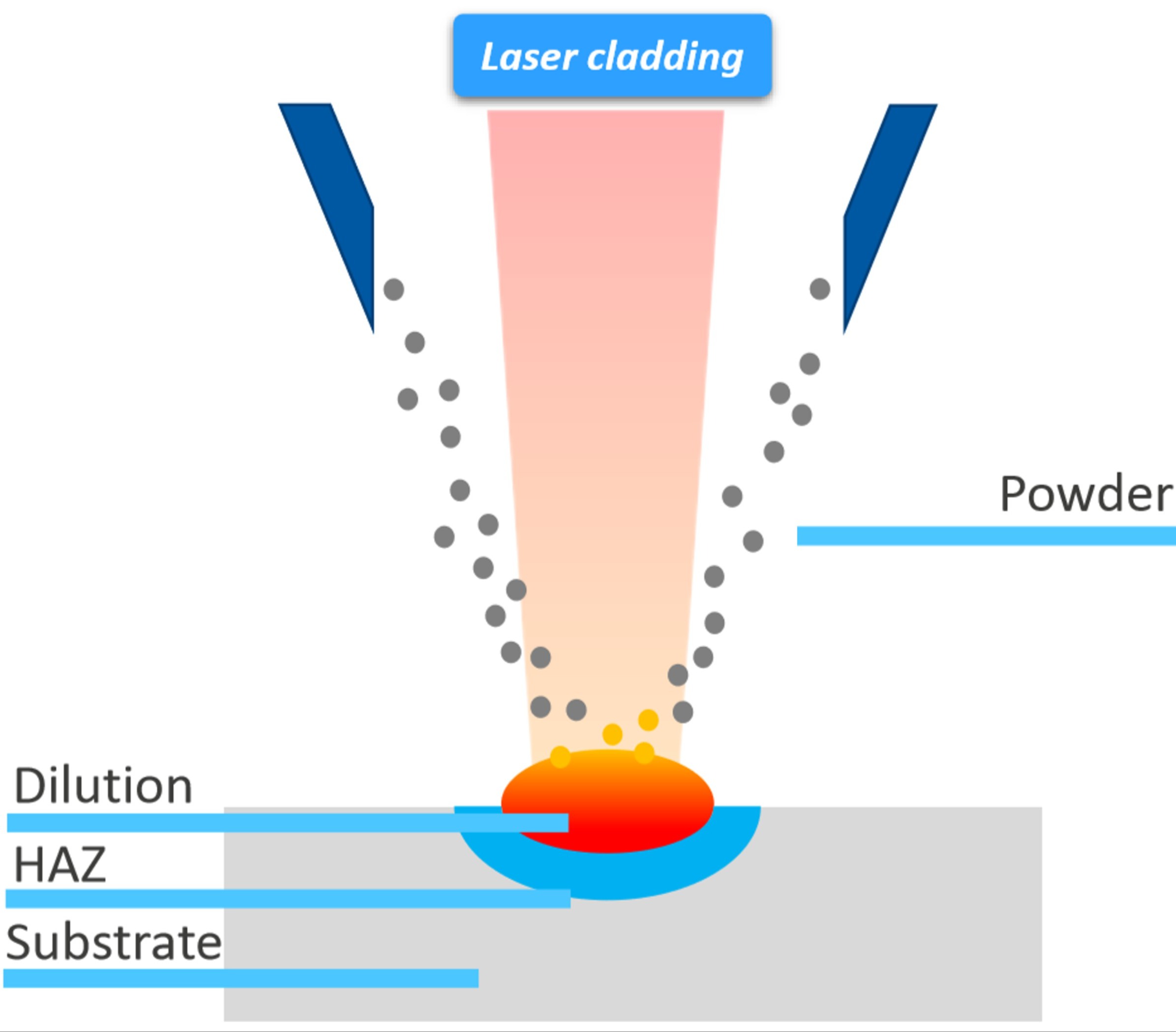

The powder used in laser cladding is normally of a metallic nature and is injected into the laser by either coaxial or lateral nozzles. The interaction of the metallic powder stream and the laser causes melting to occur and is known as the melt pool. This is deposited onto a substrate; moving the substrate allows the melt pool to solidify and thus produces a track of solid metal.

Minimal Heat

Input Laser Cladding allows power densities that are not typically possible with conventional thermal procedures resulting in minimal heat input, minimal distortion and avoidance of post weld heat treatments.

Advantages of Laser Cladding Technology

- Automically bonded to the substrate.

- Fully dense deposit.

- No under corrosion possible.

- Low heat input and distortion.

- Low material dilution (<1%).

- Used for new and repair applications.

- Surface as well as edge build-ups.

- Near net-shape deposit, less finishing effort.

- High process control and reproducibility.

- Has a minimal effect on the characteristics Of the base material, compared to PTA or Welding.

- Post-weld heat treatment is often eliminated.

Laser Cladding System Solutions with Total Support

Our Laser Systems and Total Support ensures the optimum outcome and performance for your application.

Materials in Laser Cladding: Performance Starts with the Right Alloy

Laser cladding technology stands out for its ability to deposit a wide range of materials with high precision and minimal dilution. By using advanced feedstock materials and tightly controlled process parameters, laser cladding can significantly enhance the surface properties of critical components — improving their wear resistance, corrosion protection, and overall performance.

What Materials Can Be Used in Laser Cladding?

Hornet’s laser cladding systems support a broad spectrum of metallic alloys, including:

Nickel-based alloys, Cobalt-based alloys, Stainless steels, Iron-based alloys, Copper, Titaniuma and Aluminium

Each of these material groups offers unique advantages depending on the operating environment and performance demands.

Materials: Key Advantages and Use Cases

These are widely used for their excellent corrosion and high-temperature resistance. Ideal for aerospace, oil & gas, and power generation applications where components are exposed to extreme conditions.

Enhanced surface properties after cladding

Regardless of the base material, laser cladding results in improved surface characteristics, including:

- Increased wear resistance

- Enhanced corrosion protection

- Improved thermal stability

- Extended service life of components

- Tailored hardness profiles for specific applications

These upgrades help reduce unplanned downtime, extend equipment lifespan, and lower overall maintenance costs — making laser cladding a valuable solution across a wide range of industries

Frequently asked questions about Laser Cladding

Laser Cladding is a metal surface enhancement process performed by applying a powdered metal material onto the base surface with a laser. It ensures a bond with minimal dilution, superficial melting, and a small heat affected zone.

Pros & Cons of

Conventional Surfacing / Hardfacing Processes

Process | Pros | Cons | Typical Materials |

|---|---|---|---|

GMAW (a) or MIG (b) | Fast, relatively high levels of deposits, user friendly | Process produces spatter and smoke, more prone to porosity. | Mild steel, nickel, stainless steel, flux cored and hardface wires. |

GTAW (c) or TIG (d) | Superior quality welds, low distortion, free of spatter and smoke, precise control of welding variables (heat). | Requires extremely clean weld surface, relatively slow process. | Primarily aluminum and some stainless steel. |

Stick Welding | Equipment is simple, inexpensive and portable, electrode provides its own flux, all weld position capable. | Produces slag which must be chipped off after welding. | Wide range of steel elctrodes, nickel, stainless steel and hardfacing materials. |

Submerged Arc | High quality, very high deposition rate (wide bread, if needed). | Limited positions, slag must be removed after welding. | Carbon steel, flux cored wires |

PTA (e) | Can be considered instead of laser cladding if the size, geometry or thickness of the hardface required falls outside the laser cladding parameters. | Lower tolerance capability and reduced material selection compared to laser cladding; potential for distortion due to higher heat input to the part compared to laser cladding. | Optimized for consistent, repeatable processes |

Electric Arc White Spray | Low heat input compared to other thermal spray processes, low potential for part distortion. | Mechanical (non-metallurgical) bond - typically 20 to 55 MPa (3000 to 8000 psi), suitable spray booth with adequate ventilation required, proper surface preparation is critical. | Nickel composite, aluminum and other matallic solid or cored wires. |

Thermal Spray (f) | Low heat input to base part, low potential for part distortion, wide range of coating materials. | Mechanical (non-metallurgical) bond - typically 18 to 83 MPa (2500 to 12.000 psi), suitable spray booth with adequate ventilation required, proper surface preparation is critical. | APS: Wide range of metallic and ceramic powders; HVOF: metallic powders including carbides. |

(A): Gas Metal Arc Welding

(B): Metal Inert Gas

(C): Gas Tungsten Inert Gas

(D): Tungsten Inert Gas

(E): Plasma Transferred Arc

(F): Atmosperic Plasma Spray (APS) or High Velocity Oxygen Fuel Spray (HVOF)