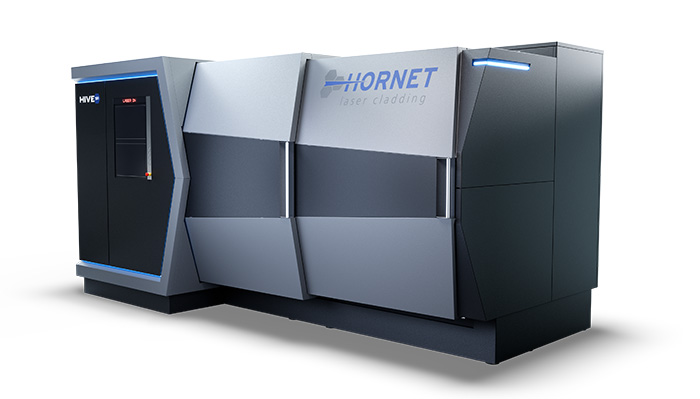

Factory-hardened reliable Laser Cladding machines

for the world's most demanding applications

Welcome to Hornet Laser Cladding! Established in 2015, we are a market-leading supplier of LASER CLADDING machine solutions.

Fully EU-compliant systems designed for 24/7 operation, avoiding the reliability risks of low-cost lightweight 'box' machines, no downtime, no excuses. Our proprietary HMI allows operators to run complex paths without a PhD in software engineering. Operational excellence over theoretical complexity. Customers receive a quality, robust, and reliable industry-ready package built on experience.

At Hornet Laser Cladding, we cover the entire process and provide our customers with a competitive advantage. We aren't generalists. We are Laser Cladding experts. Dedicated expertise for critical and high-value applications.

Our technologies

The Hornet Difference

We supply turnkey systems across the world of all sizes and configurations which gives Hornet Laser Cladding an enviable installed base of systems and customers.

Engineered with our customer requirements for performance and budget firmly at the fore, our systems can be tooled to offer standard or high power EHLA, conventional cladding, wide beam cladding, wire cladding and internal cladding in any combination. We have supplied machines up to 26m in length and commonly with up to 10 axis fully interpolated and seamlessly integrated. All our machines include our class leading HMI and easy programming modes ensuring your step into Laser Cladding is an easy one.

View our technology solutions

Applications

Laser cladding is a versatile technology with a wide range of applications across various industries. It is a cost-effective technology that creates high-performance alloy surfaces on inexpensive metal substrates without altering the properties of the substrate. This reduces costs, conserves precious & rare earth materials, and contributes to a sustainable circular economy.

Bearings

Laser cladding enhances bearing performance, reduces non-ferrous metal use, and improves energy efficiency and durability.

Hydraulics

Laser cladding offers superior wear and corrosion resistance, minimal distortion, environmental benefits, and quick turnaround for hydraulic rods.

Ground Engaging

Laser cladding enhances durability and protection for earth-moving equipment, reducing wear, impact, and corrosion under extreme stress.

Pumps & Valves

Laser cladding enhances durability, wear, and corrosion resistance for oil, gas, and petrochemical industry components, ensuring cost-effective restoration.

Rolls

Laser cladding protects paper and steel industry machinery from corrosion and wear, extending equipment life and reducing maintenance costs.

Turbines

Laser cladding enhances turbine blade durability, wear & erosion resistance, and reduces maintenance costs in renewable energy applications.

Become part of our

owners club

And recieve personalized services:

- Technical support

- Application development

- Knowledge transfer

- Training academy

- Discounts on aftercare & spares

Latest news & blogs

No More Downtime: Hornet Mobile™ Laser Cladding System

At Hornet Laser Cladding, we understand that innovation isn't just about what you do, but where you can do it. For too long, repairing large-scale, immovable, or hard-t...

Introducing The Hive™: Laser Cladding System

D&T Hardchrome Adds Second Hornet Laser System

Valued customers we partner with

Is laser cladding environmentally friendly?

Laser cladding is widely considered an environmentally friendly manufacturing technology, particularly when compared to conventional surface coating methods like hard chrome plating. Its eco-friendliness stems from its reduced waste generation, elimination of hazardous materials, and improved energy efficiency.

Key environmental benefits of laser cladding:

No hexavalent chromium (Cr VI): Traditional hard chrome plating uses highly toxic and carcinogenic hexavalent chromium. Laser cladding completely eliminates this hazardous substance from the process.

Reduced emissions: Since it does not rely on electrolytic baths or chemical solutions, laser cladding avoids the harmful airborne emissions and wastewater associated with conventional plating.