Laser metal deposition for process machinery

Laser metal deposition solutions for the paper and steel industries offer exceptional protection for machinery components against corrosion and wear, significantly extending the life of critical equipment such as rollers, molds, drums, and mandrels. This advanced technology provides excellent durability in high-temperature and high-wear environments, helping steel manufacturers reduce maintenance costs and minimize unplanned downtimes.

Upgrade your Rollers

Laser metal deposition is used to enhance the wear resistance and durability of rollers used in mills. This process extends the service life of rollers by providing a hard, wear-resistant surface.

Improve resistance to wear and corrosion

Drums used in the steel industry benefit from laser metal deposition by receiving a protective layer that improves their resistance to wear and corrosion.

Extended service life

Mandrels, which are critical components in the steel manufacturing process, can be coated with laser metal deposition to enhance their performance and longevity.

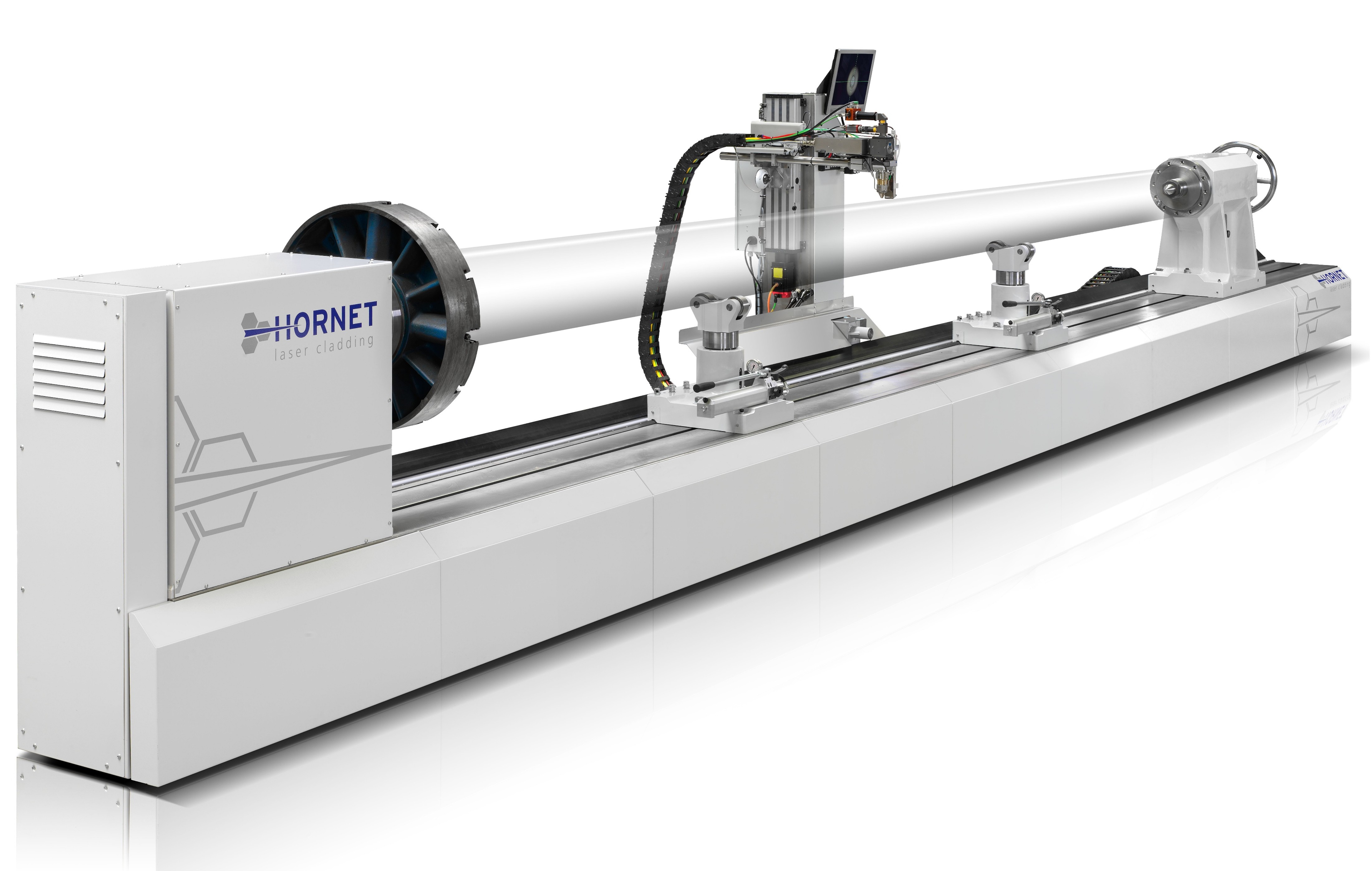

Laser Cladding System Solutions with Total Support

Laser Metal Deposition protects paper and steel industry machinery and equipment from corrosion and wear, extending equipment life and reducing maintenance costs. Our Laser Cladding Equipment and Total Support ensures the optimum outcome and performance for your application.

Frequently asked questions

No. The old chrome must be completely ground off down to the base steel because the laser will cause the chrome to vaporize and create massive porosity in the new deposit.