D&T Hardchrome, a pioneer in advanced surface engineering, has taken a significant step forward in its growth journey with the installation of a second Laser Cladding system, delivered by Hornet Laser Cladding BV.

In 2019, D&T Hardchrome became the first company in Australia to implement the EHLA process, setting a new benchmark in precision and productivity. The original Hornet system has operated at full capacity—two shifts a day, six days a week—since its commissioning. Now, five years later, the company has expanded its production capabilities to meet increasing demand.

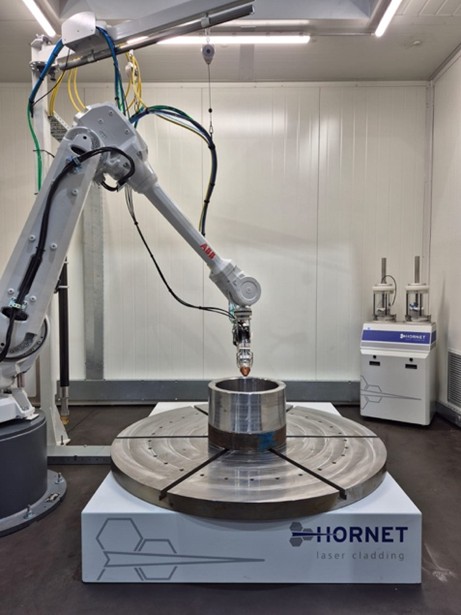

The newly delivered system features cutting-edge laser cladding technology, including a robot-controlled manipulator with dual processing heads capable of handling components up to 10 tonnes. Designed for both internal and external cladding, the turnkey solution is equipped with advanced software for intuitive programming of complex geometries, recipe management, and an optical closed-loop control system to ensure consistent, high-quality results. Notably, this is the first machine in Australia to incorporate the revolutionary SimpliFlow powder feeder, offering enhanced precision and efficiency in material delivery.

We are proud to continue our partnership with D&T Hardchrome and support their commitment to innovation and excellence. This second system not only boosts their capacity but also introduces new possibilities for advanced manufacturing in the region.

Hornet Laser Cladding congratulates D&T Hardchrome on this exciting milestone and looks forward to supporting their continued success.